Accessories |

|

| |

| |

| |

| • Industrial applications where ultra-dry air or very low dewpoint (-40°F pressure dew point) is required. |

| • Installations where downstream air systems are exposed to ambient temperatures down to -40°F (-40°C). |

| • Pneumatic instrumentation and controls . |

| • Paint spraying, plastic and epoxy coatings, powder coating. |

| • Engineering and scientific laboratories . |

| • Controller " transmitters, valve positioners, operator, air bearings

and air motors . |

| • Audio-Video cassette rewinding machines/ CD Plants . |

| • To protect Actuators |

| • Food Packing! Processing I Pharmaceuticals I Tablet Packing. |

| |

| Features |

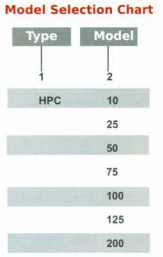

| • Wide range of sizes 10 suit your requirement 10, 25, 50, 75, 100, 200 SQ'M and many more. |

| • Calibrated needle valve to

adjust purge flow to actual outlet f1(1W and pressure conditions . |

| • Overlapping cycle time to provide constant

downstream pressure and dew point. |

| • Normally open bottle valves allow constant air flow through dryer even

in electricity failure . |

| • Integral wall mounting models are available to save floor space . |

| • Easy installation - just make the air connections and plug in the electrical power cord. - Lightweight and compact. Inlet and outlets are

from top where as purging is from down . |

| • Facilitates the water flu hing out during purging . |

| • Trouble free and reliable performance. |

| |

| |

|

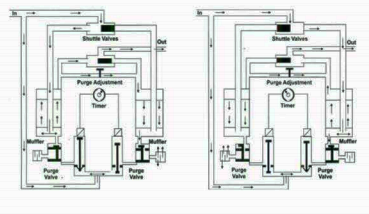

Two towers, filled with a desiccant which adsorbs water

vapour, provide ultra-dry air (-40°C pressure dew point) for

operation of sensitive pneumatic devices. Inlet air i dried in

one tower during a drying cycle. Simultaneously, the desiccant

is dried in the other tower during the regenerative cycle. An

electric timer automatically cycles inlet air between the towers

every two minutes providing a continuous supply of dry air.

Constant downstream pressure and dew point arc maintained

by overlapping the cycle times (both towers are pressurized

briefly before changeover). During the 'regenerative cycle' the

desiccant is dried by purging with a small amount of dry air

from the on-line tower (Dry air passes through the desiccant

and Is exhausted to atmosphere). A calibrated needle valve

allows the amount of air used for purging to be kept to a

minimum. i.e 5-8% |

|

| |

| |

| Technical Specification |

| |

| Inlet 'Pressure |

Min. 1,4 Kg/Sq.cm

Max. 10 Kg/Sq. em. |

| Dew Point |

Outlet-40°C |

| Capacity |

10,25.50,75,100,125,200

CFM for Heat less Type .

More than 200 to 5000 CPM.

Heated Low Purge Type (HOC) |

| Ambient Temp |

Max. 50°C |

| Size |

Compact |

| Desiccant |

Activated Alumina |

| Type |

Heatless Regenerative

Heated Low Purge |

|

|

|

| |

| |

|

| |

|

| |

| |

| |

| |